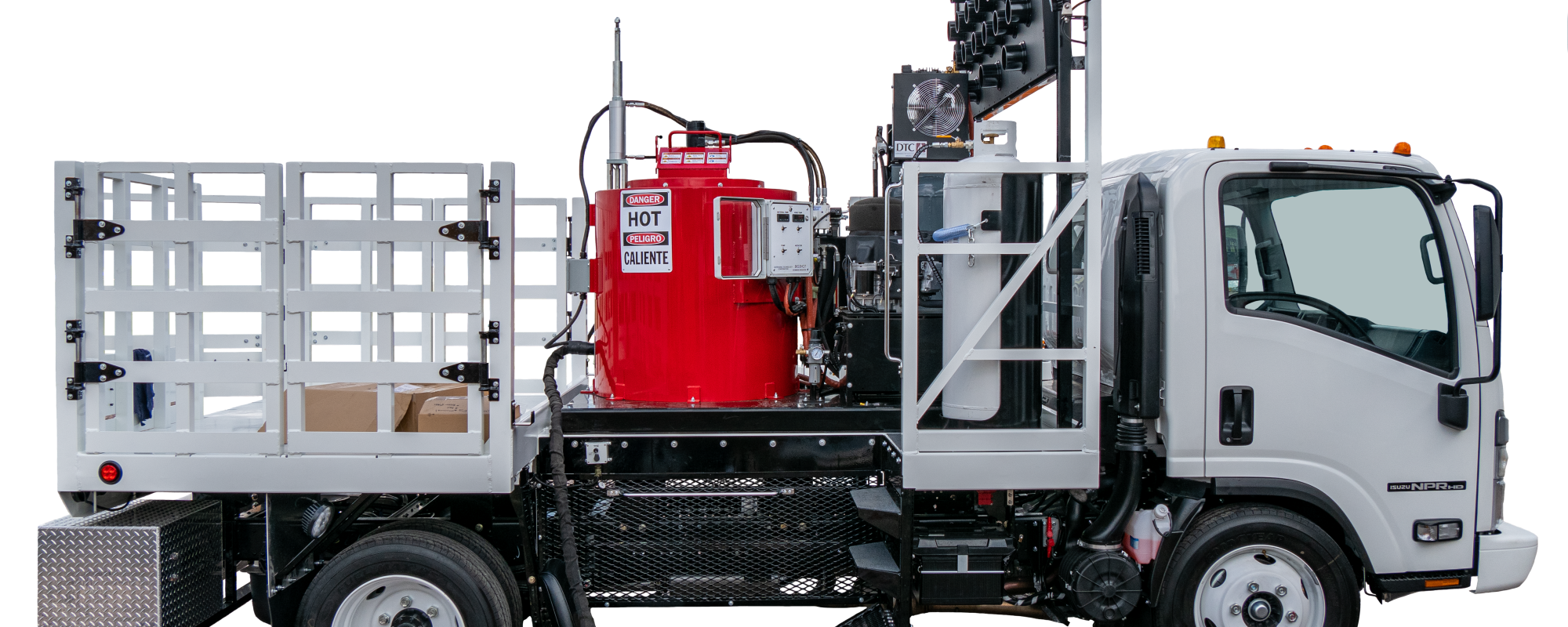

Designed for efficiency and ease of use, our RPM truck saves time and money every time it hits the road.

SPECIFICATIONS

specifications are subject to change.Chassis

- Isuzu FE204; NPR HD Gas Reg

- 14.500 pound GVWR

- 132.5 inch wheel base

- 170 amp alternator

- 38.6 gallon fuel tank

- GMP-T-V8 Gas engine, 6 liter, 8 cylinder, 350 HP and 425 lb/ft of torque

- Model 6L90-E Hydra-Matic transmission

- 225/70R 19.5G tires with steel wheels, and back-up alarm

Deck

- Smooth aluminum with grip material strips

- 96"x151" deck

- 8" risers to provide room for the suspension

- (2) operator baskets mounted in front of the rear tires

- Basket is no greater than 6" from the pavement during operation, providing EZ application

- Baskets adjustable depending on need

- Swing gates hinged out away from the deck

- Powder coat color decided by customer

- (2) 18"x18"x24" toolbox mounted on rear

Positive Displacement Pump

- Adjustable output up to 13 cubic inches per stroke

- Shot size adjustment with mechanical stroke limiter for simplicity and ease of service

Bituminous Supply System

- Capable of heating up to 500lbs of bituminous material, air jacketed melter

- Welded steel melting tank

- Melting tank has a hinged 12"x8.5" loading hatch with a total open area of 102 square inches

- Lid is designed to close away from operator with locking pin

- Melting kettle requires an agitator with the bypass always "ON" which prevents scorching of the material

- The tank is LP fired using and impinged jet-type burner with an output of 150,000 BTU/hr

Agitator

- Melter kettle comes equipped with a continuous, full sweep hydraulic agitation system to prevent filler from falling out of suspension, and to speed the melting rate of the material

Heated Output Hose

- 10 foot hose with an applicator pistol

- A type "J" thermocouple-type temperature sensor is attached to the stainless-steel over-braid

- (1) Duck bill applicator

Air Compressor/Auxiliary Engine

- Kawasaki air-cooled, four cycle, single cylinder engine

- 18 HP at 3,600 RPM

- Propane operation with 100lb propane tank

- High efficiency air-cooling fan

- 14-20 CFM air compressor

Hydraulic System

- .66 displacement rotary piston hydraulic pump; belt driven

- 8-12 gallon oil reservoir

- By-pass ball valve for easy auxiliary engine

- Oil cooler 12 VDC assembly

- Bituminous pump

Electrical System

- The melter applicator has digital electronic temperature controllers that will automatically regulate the material temperature and the hose temperature

- The material thermostat controls burner ignition automatically up to 450 deg. F

- Pumps are controlled by a 12-volt DC, 4-way electrically operated hydraulic valve

Arrow Board

- National Signal 25 LED lamp 3 foot by 6 foot actuated arrow board with controller in chassis cab

Intercom System

- David Clark Model U3800 three station with one H3492 single earpiece headset & one Model H3432 dual earpiece headset

- Three headset storage hooks

Safety Light System

- Two Whelen Model L41AP amber LED 360-degree strobes on front of deck

- Two Whelen Model 70A02FAR amber directional light heads on rear deck

- One Whelen Model LINV2A mini amber LED 180-degree strobes on baskets, one per basket

LED Work Light System

- Six Hella 2,000 lumen LED work lights